Connections

Back to Back Spacer

When projects are struggling for height, for instance in basements and lofts, it is often preferable to replace a deep beam with two smaller beams. However, to ensure stability and resistance to buckling, these beams need to be bolted together. This is where a Spacer is used, which is usually welded to one of the beams. The bolts are typically 600mm apart.

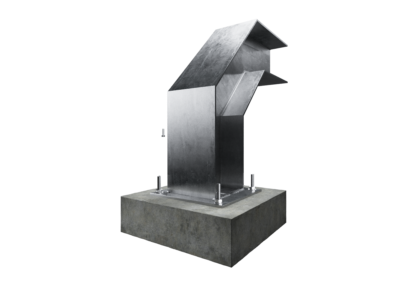

Base Plate

Base Plates are used as support for columns coming off a concrete pad or foundation. To ensure longevity and stability, it is essential to leave a gap of around 20mm – 30mm between the concrete and the steel plate, which can be achieved using shims and wedges.

End Plate

An end plate is used to anchor the end of a beam to a wall, and is also part of the ‘End Plate Connection’.

Angle Cleat

An Angle Cleat is used to bolt one beam into the side of another beam. Cleats are made from RSA Sections (angles), which are then bolted to both beams. In cases where only one side needs bolting, only one cleat will be required, and for some projects it is preferable to weld the cleats to the end of a beam rather than bolting them.

Crank 90°

A 90° crank is a typical crank but with two kinks. In a 90° crank the top member will be horizontal and the bottom vertical. Cranked beams are most frequently used to support roof structures, therefore the angle of the middle member needs to follow the pitch of the roof. It is crucial that full penetration welds are used with these connections to ensure the crank will carry the load.

Bottom Plate

A bottom plate is added to a beam in order to support brickwork or timber joists. The bottom plate is stitch welded to the beam and is often offset to one side so that the brickwork is sufficiently supported.

Top Plate

A Top Plate is commonly used when a beam is smaller than the wall and needs to be resized.

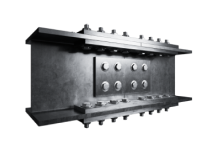

Splice

Splices are used when a beam is too heavy or too long to install or transport safely. The flange plates need to be at least the same thickness as the beam’s flange, and the same rule applies to the web plates.